Loading

Have you ever seen an historical monument and wondered at the exquisite marvels of architectural beauty, the intricately sculpted jharokhas, the magnificently detailed cornices, the tall, majestic domes and the gargoyle-like columns? All these complex and ornate designs, in today’s world can be so widely reproduced because of the versatility of GFRC. It is being used since the past thirty years to make such designs possible.

GFRC (Glass Fiber Reinforced Concrete) is a slurry of cement and sand reinforced with glass fiber. It was first created in Russia in the 1940s. It became popular during the 70s. Its primary components are concrete, polymer aggregate and glass fiber reinforcement it has varied applications in construction because of the versatility of its material. Its high tensile strength, impact resistance, moisture absorption and lightweight quality makes it a perfect fit for artistic architectural designs, renovation work, construction of wall panels and countertops. It also improves color performance and can be used to give any desired texture. GRC is also sustainable because it uses less cement and more recycled material. It is available in sprays and as a premix.

What makes it so unique and popular?

The main feature that makes GRC so versatile is its unique composition. Glass fiber also known as fiber glass is a robust material which is water-resistant, light-weight and extremely strong. Fiberglass mixed with polymers is usually used in boats, but the absence of ‘alkaline resistance’ specifically makes it weaker and less durable. When alkaline-resistant glass fiber was added to Portland cement and sand, it gave rise to the most versatile reinforced concrete that was ever made.

It is mainly used for decorative panels, such as fireplace surrounds and window surrounds, artistic countertops, concrete furniture and wall brackets that are also commonly available in marketplace for decoration in homes. Artificial landscapes that require faux rocks, fountains and urns are made through GFC. It is also used for cornices, architectural accents, domes and pillars and also in small scale household products.

1. Toughness

The reinforcement of alkaline-resistant glass fiber in the concrete matrix makes it less susceptible to cracks. Although there won’t be any cracks the material can be easily cut without chipping.

2. Surface Finish

The dynamic range of colors and textures that are possible with this material gives it an aesthetic appeal. It can seamlessly match the color and texture of buildings it is put upon. The likelihood of surfaces having holes and bumps is negligible.

3. Can be molded into any shape

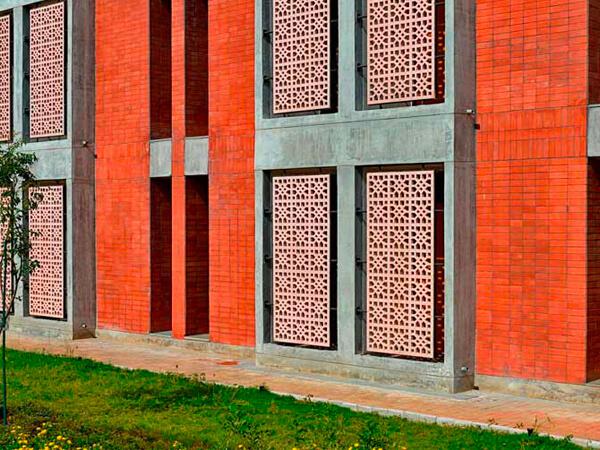

This is one of the primary reasons why GFRC is most preferred. It can be very easily casted to any desired shape. It is widely used in ornamental designs, as it can efficiently and quickly replicate intricate designs, such as the traditional, masterful designs that are found in historical buildings or monuments. It also has its uses in modern design as it is most common application is in panels and grills.

4. Weight

Due to the light weight of the material, there is a remarkable benefit to the structure, it is used upon. It reduces the resultant weight of the end product. Other sorts of reinforcements like steel reinforcements increase the weight of the foundation, making it thicker and difficult to transport, GFRC products on the other hand weigh a fraction when compared to these. Thus, the lighter foundations significantly reduce the shipping costs.

5. Strength

GFRC has a very high strength to weight ratio. It doesn’t crack under normal pressure. It can be used in buildings designed to stand withstand seismic loads, because of its high tensile strength. It can be also used in reducing the thickness of the concrete it is used upon and providing increased tensile strength and less weight. It is often used in countertops where its thickness can be reduced to half.

6. Sustainability

GFRC uses less cement and more recycled materials making it completely recyclable. It does not emit any pollutants in the atmosphere, both during production and application. Due to its low-weight, the carbon emissions due to transportation are also reduced.

7. Durability

GFRC has increased durability due to low alkaline cements. It can outlast any concrete object and even cast stone. Water cannot permeate through it and there is no corrosion which is often a huge concern when it comes to traditional concrete. It can also withstand any extreme weather conditions without any damage.

This unique compound due to its thin casting and plethora of benefits, gives the best results at affordable prices. It is easily moldable and reduces onsite labor requirements making the whole process quick and efficient which is why it is so popular amongst design enthusiasts and construction workers. People can spruce up their homes with beautiful architectural designs at affordable prices because of GFRC.

Also Read: Modern White Concrete Architectures Across the World